|

|

|

|

|

|

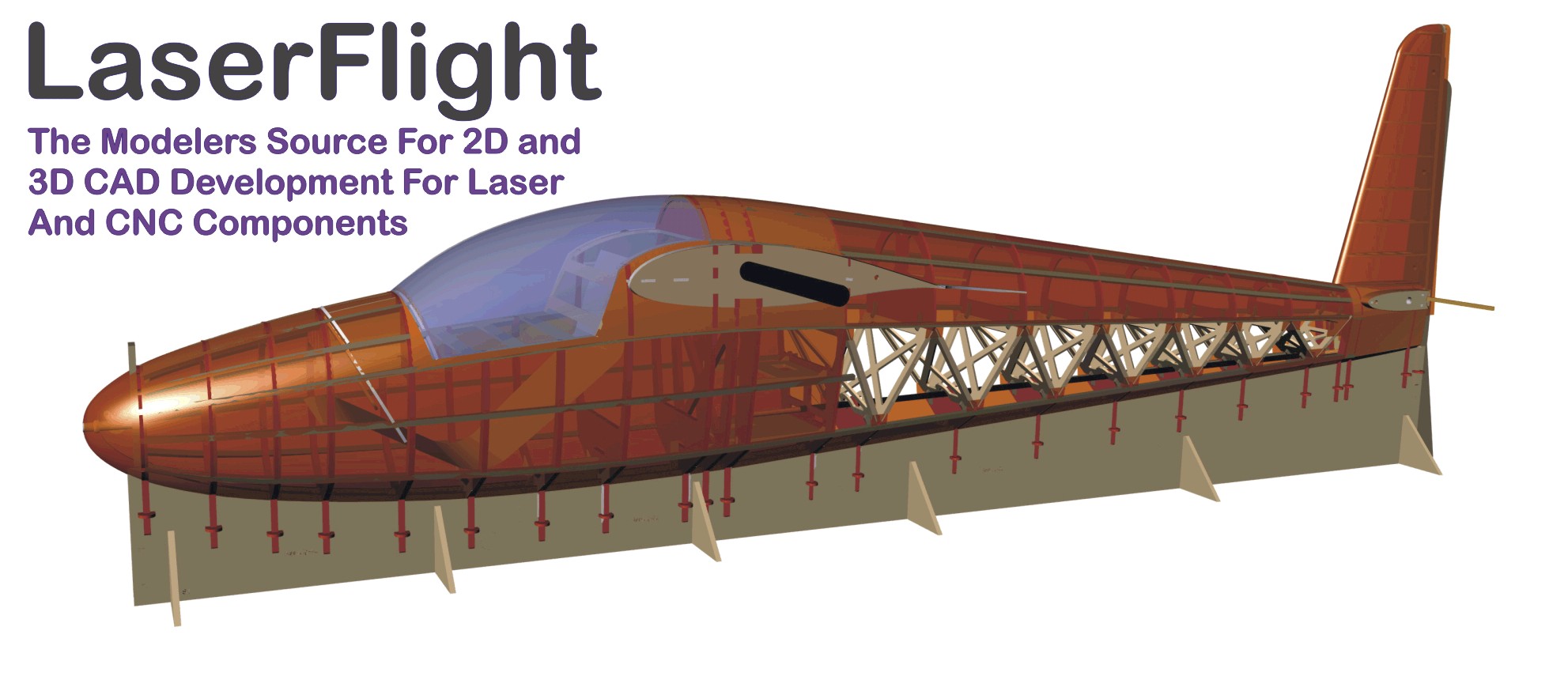

3D Re-Plan And Parts Service What Is The Service? If you have come to this service then we assume you have a very old, possibly hand drawn, distorted or skewed set of plans and you want a set of parts that you can be confident will fit together well and create a well engineered model. In the following example, we have assumed a model airplane plan has been sent to us but the same applies for many other model types. Our process is very similar and in general simpler if the model is not an airplane! The Steps We Take! 1). Step one in the process (again, assuming a model airplane) is to create a partial 3D CAD model of the fuselage or fuselages (if there's more than one), nacels, booms, pods - whatever exists is in the model per the plan. We model everything except flying surfaces (wings, stab(s) etc). We then use these partial 3D CAD models to create a good set of formers/bulkheads/mounts - again, whatever is needed based on the plan you send us. We do NOT create a full 3D model - only enough to create the parts for these non-flying surface components). This process ensures that the parts are well designed, symmetrical (if symmetry is required for the part), straight, correctly sized, and correctly slotted. We develop a set of parts and export those parts to a CAD file that can be used for Laser, CNC or hand cutting (after printing). 2). the second step is to use another tool to create the flying surfaces per the structure defined on the plans. This would include wings, stabilzer(s), rudder(s), vertical fins, canards - again, whatever is needed for the model and again, based on the structure drawn in the plans. 3). Step three of the process is to integrate the flying surfaces created in step 2 with the partial 3D CAD models created in step one. This step is used to ensure the mounting structures in the non-flying surface components (fuselages, stab mounts etc) MATCH the mounting receivers in the flying surfaces. 4). Once the verification is done in step 3, we export the components to a CAD file for Laser, CNC or hand cutting. There will, very frequently be minor differences between the components drawn on the plans and the components we generate. Primarily this is because we have the ability to enhance the structures we create - options that weren't available when the original plans were drawn and options that can add value to you as a builder and are just easier to do with teh advent of Laser and CNC cutting services. What Else Do We Offer? Additionally, we have the ability to offer further enhancements, such as building jigs. We offer a few enhancements that can make your model easier to build or look more authentic. We've included these enhanced features in our selections below. So How Do I Get Started? As you can imagine, there is a fair amount of work involved in the process and as the complexity of the model increases, so does the amount of work. We have therefore created a pricing structure that is primarily based on the TYPE of model you want us to Re-Plan. However, before you start the transaction below, you will need to scan the plans ready to send to us. We have a set of instructions that you should review first before heading to the office supplies store to scan your plans. Please do not follow the second recommendation in these instructions that detail a process to copy and patchwork the parts in the plan sheets. We need to see the plans as you see them in order to make this process work. Once you have determined the model type from the chart below, select the option that best describes your model and complete the payment transaction. You will then be directed to an Upload Page where you can send us your scanned plans. Model Type Single fuse with nose mounted propeller engine, single forward wing, single rudder/stabilizer, fixed undercarraige Single fuse with nose mounted propeller engine, single forward wing, single rudder/stabilizer, Retracting undercarraige Dual wing mounted propeller engines in nacels, single fuselage, single forward wing, single rudder/stabilizer, fixed undercarrage Dual wing mounted propeller engines in nacels, single fuselage, single forward wing, single rudder/stabilizer, Retracting undercarrage Dual fuse mounted propeller engines in fuse (Push/Pull), single forward wing, single rudder/stabilizer, fixed undercarrage Dual fuse mounted propeller engines in fuse (Push/Pull), single forward wing, single rudder/stabilizer, retracting undercarrage Three propeller engines (two on wings, one in fuse), single forward wing, single rudder/stabilizer, fixed undercarrage Three propeller engines (two on wings, one in fuse), single forward wing, single rudder/stabilizer. Retracting undercarrage Continue list and complete it.

|

© Copyright 2007-2010, www.LaserFlight.com. All rights reserved.